Enhance Your Ride with Limited Slip Friction Modifier

If you’re looking to elevate your vehicle’s performance, incorporating a limited slip friction modifier could be a game-changer. Not only does it promise impressive differential performance enhancements, but it also leads to notable noise reduction and smoother handling. Whether you’re navigating tight corners or cruising down the highway, the right friction modifier can make all the difference.

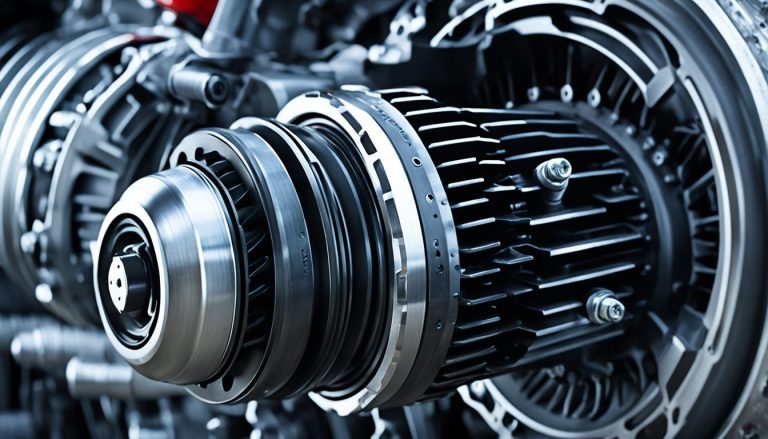

Your car’s differential is pivotal in ensuring that power is distributed evenly to your wheels, allowing for nuanced control and drive stability. However, without proper lubrication, this can lead to noise and increased wear. Here’s where the magic of friction modifiers come into play—they work within your differential’s lubrication system to quell those unwanted sounds and give you a silky-smooth ride.

Take the leap towards exceptional vehicular performance and comfort with a friction modifier tailored for your limited slip differential. The smoother operation and extended lifespan of your differential components are just a few benefits that await. Ready to take your drive up a notch? Let’s delve into how this seemingly small addition can make a substantial impact on your driving experience.

Key Takeaways

- Upgrading to a high-quality limited slip friction modifier can significantly improve handling and reduce differential noise.

- Friction modifiers facilitate smoother clutch plate operation, preventing vibration and harsh sounds.

- Adequate lubrication via friction modifiers leads to less wear and tear, prolonging the life of your differential system.

- Choosing the appropriate friction modifier ensures optimized performance for your specific vehicle make and model.

- Periodic application and maintenance of friction modifiers can sustain the enhanced differential performance over time.

Understanding the Role of Limited Slip Friction Modifier in Your Differential

When it comes to optimizing the performance of your vehicle’s limited slip differential, understanding the significance of a limited slip friction modifier is essential. This specialized additive plays a pivotal role in enhancing your driving experience by improving the behavior and longevity of the differential mechanism. Let’s delve into what makes these additives so crucial.

What Is a Limited Slip Friction Modifier?

A limited slip friction modifier isn’t merely an additive; it’s a crucial component that gives your gear oil the ability to perform at its peak within the environments of a limited slip differential. By balancing the friction reducing additives within the gear oil, this powerful solution allows for the efficient operation of the clutch plates, thus preventing unpleasant noises and vibrations.

How Friction Modifiers Affect Limited Slip Differentials

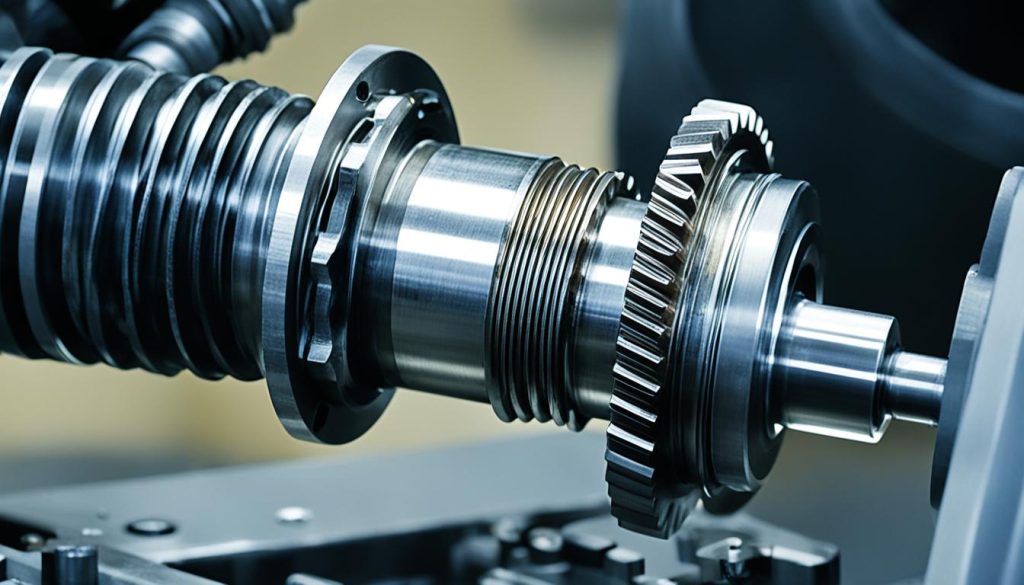

By integrating the right differential fluid friction modifier into your system, you significantly alter the engagement dynamics of your differential. This fine-tuning of the components results in a smoother transition between the locked and unlocked states. Whether you’re taking sharp turns or handling your vehicle under stress, a friction modifier ensures that your differential responds in a manner that’s both efficient and gentle on your car’s internals.

The Importance of Choosing the Right Friction Modifier

Selecting an appropriate friction reducing additive can’t be overstated. With varying formulations on the market, settling on the right one can mean the difference between an averagely performing differential and one that exhibits enhanced smoothness and reliability over time. The right gear oil friction modifier ensures that your differential operates effectively without the chatter and wear typically associated with poor lubrication, thus conserving the mechanism’s integrity.

The intricate dance between differential fluid additives and limited slip mechanisms is a testament to modern automotive engineering. Ensuring you’ve armed your vehicle with the right products will prolong the life of your differential, letting you enjoy uninterrupted and top-notch performance on the road.

Choosing the Correct Friction Modifier for Your Vehicle

Understanding which limited slip differential additive is best suited for your car is essential for maintaining a responsive and high-performing drive. The type of additive required can vary based on the specific limited slip differential you have installed, such as a Trac-Lok or Eaton TrueTrac. Notably, an increasing number of synthetic gear oils come with a built-in gear oil friction modifier, potentially bypassing the need for separate additives.

However, if an oil change doesn’t eliminate differential chatter, or if your vehicle’s manufacturer recommends a specialized product, it becomes imperative to select and use a dedicated friction modifier. Here are some tips to help you choose the right one:

- Check your vehicle’s manual for specific recommendations concerning the gear oil friction modifier.

- Look for products that are compatible with the type of differential in your vehicle.

- If you use a synthetic gear oil, confirm if it requires additional modifiers, as some may already minimize chatter and enhance smoothness.

- For persistent issues, consider a high-performance additive that is known to tackle problems associated with limited slip differentials effectively.

Remember, the key is to avoid unwanted friction and ensure smooth transitions during cornering. When chosen correctly, a friction modifier can significantly enhance your vehicle’s drivability and extend the lifespan of your differential.

Limited Slip Friction Modifier: Installation and Best Practices

Ensuring your vehicle runs smoothly involves regular maintenance, particularly when it comes to your differential. The right limited slip friction modifier application can make all the difference in vehicle performance. Here’s how to properly maintain your differential and apply limited slip modifiers to keep your ride in peak condition.

Step-by-Step Guide to Adding Friction Modifier

Application of a limited slip friction modifier is a straightforward process but demands attention to detail:

- Verify that you’re using the appropriate friction modifier for your vehicle’s specific differential type.

- Drain the existing differential fluid completely before proceeding.

- Refill the differential with the correct grade of gear oil for your vehicle, which may be synthetic or conventional.

- Add the recommended quantity of limited slip friction modifier to the new gear oil.

Common Mistakes to Avoid During Installation

Proper application is crucial to avoid potential missteps that can affect friction modifier performance:

- Do not exceed the manufacturer recommended amount of friction modifier, as this can lead to reduced differential performance and potential damage.

- Ensure the gear oil and friction modifier mixture is at the correct fill level—too much or too little can both be problematic.

Periodic Maintenance for Optimal Performance

Differential fluid maintenance is not a one-time affair. Regular checks are needed to ensure continued effectiveness:

- Change your differential fluid and reapply the friction modifier at intervals suggested by your vehicle manufacturer.

- Keep an eye on the differential’s performance—any change might indicate a need for maintenance.

- Remember, over time, friction modifiers can lose efficacy and will require replenishment to maintain the advantages they deliver in limited slip differential maintenance.

Following these guidelines will ensure your differential runs smoothly, providing both enhanced performance and longevity.

The Debate Over Synthetic vs. Conventional Gear Oil

When you’re faced with the decision of choosing the right differential fluid for your vehicle, the ongoing debate between synthetic gear oil and conventional gear oil comes into play. Both have their champions and critics, with strong opinions regarding viscosity, lubrication qualities, and the role of additives in performance.

Synthetics offer a high-tech solution with a reputation for reducing operating temperatures and providing superior protection for your differential. Known for their cleaner formulation, these oils are less likely to contain impurities that could affect performance. But the question remains, does the slick nature of synthetic gear oil replace the need for limited slip friction modifiers?

In contrast, conventional gear oils have long been the standard choice, and many argue that they’ve done the job well for decades. However, they are susceptible to breakdown at higher temperatures and may not match the longevity offered by synthetic formulations. This invites further inspection into the type of differential fluid choice that best suits your vehicle’s needs.

| Synthetic Gear Oil | Conventional Gear Oil |

|---|---|

| More consistent performance at varying temperatures | May thin out or thicken, depending on temperature changes |

| Longer change intervals, potentially saving time and money | Shorter change intervals, requiring more frequent maintenance |

| Typically higher upfront cost but may lead to cost savings over time | Lower upfront cost but might be more expensive in the long run due to maintenance |

| May render additional friction modifiers unnecessary | Often requires the addition of friction modifiers for optimal performance |

The selection between synthetic and conventional varieties is not just about personal preference. It’s a decision that affects your differential’s efficiency, performance longevity, and in some cases, warranty compliance. Be sure to consult your vehicle’s manual or speak with a trusted mechanic when deciding on your differential fluid choice. This way, you ensure that your gears are running smoothly, and you’re maximizing the health and longevity of your vehicle.

Maximizing Differential Longevity and Performance with Additives

As a vehicle enthusiast, you’re always looking for ways to bolster your ride’s performance. It’s crucial to go beyond just relying on a limited slip friction modifier and consider the full range of gear oil enhancements that can significantly reduce differential wear and optimize your car’s driving dynamics. A deep dive into the various additives will illustrate how each component works to secure the advantages of a well-maintained differential system.

Understanding Gear Oil Additives Beyond Friction Modifiers

Gear oil isn’t just a singular substance; it’s a blend that includes an array of additives, each serving a unique purpose. Anti-wear agents, for example, provide a layer of protection against metal-to-metal contact, while rust inhibitors shield your differential’s internal components from corrosion. Viscosity stabilizers ensure a consistent performance across a range of temperatures. These gear oil enhancements collectively extend the lifespan of your differential significantly, proving that there is more to maintenance than the friction modifier effectiveness alone.

The Impact of Friction Modifiers on Wear and Tear

Indeed, the core benefits of friction modifiers can’t be overstated. Their primary role is to smooth out the interaction between the clutch plates, significantly cutting down on the wear caused by friction. This translates to a quieter operation and less strain on the components, bolstering your differential’s resilience. The advantages of these additives render them an excellent preventative measure, curbing the onset of future differential repair and potential breakdowns, and thus, safeguarding your investment.

Recognizing When Your Differential Needs More Than Just a Friction Modifier

Even though regular use of friction modifiers aids in maintaining your differential in tip-top shape, there may come a time when it signals the need for more comprehensive care. Symptoms such as unexpected noises or the dreaded chattering around corners are tell-tale signs that your vehicle may require additional attention or even a distinct type of friction modifier. In these instances, seeking professional guidance is paramount, as timely intervention can prevent more severe damage and costly repairs down the road.

FAQ

What is a limited slip friction modifier and why do I need it?

A limited slip friction modifier is a specially formulated additive that enhances the lubricating properties of gear oil in limited slip differentials, ensuring smoother clutch plate interactions and reducing noise and chattering. It’s an essential component for maintaining the performance and longevity of your vehicle’s differential.

How do friction modifiers affect the performance of limited slip differentials?

Friction modifiers alter the frictional characteristics within the differential, increasing the threshold for clutch slip, promoting smoother engagement, and reducing harsh transitions between locked and unlocked states. This leads to better handling, reduced noise, and minimized wear on the differential’s internal components.

Why is it important to choose the right friction modifier for my differential?

Using the correct friction modifier ensures that the differential’s clutches operate properly and that there’s a balance between effective lock-up and smooth operation. This prevents undue stress, reduces noise, and prolongs the life of your differential.

How can I correctly add a friction modifier to my vehicle?

To add a friction modifier, first confirm you have the right product for your vehicle. Drain the old differential fluid, refill with the proper grade of gear oil, and then add the recommended amount of friction modifier according to your vehicle manufacturer’s guidance or differential specifications.

What common mistakes should I avoid when installing friction modifier?

Avoid using more friction modifier than recommended, as overfilling can decrease performance and cause damage. Also, make sure to maintain the correct differential fluid level, especially when using synthetic oils, where less volume may be needed.

How often should I perform maintenance on my differential, and how does a friction modifier fit into that schedule?

You should perform periodic maintenance on your differential according to your vehicle’s recommended schedule, typically during fluid changes or inspections. The effectiveness of friction modifiers can diminish over time, so they may need to be added or replaced to maintain smooth differential operation and prevent component wear.

Is there a significant difference between synthetic and conventional gear oil when it comes to differentials?

Yes, synthetic gear oils generally offer better temperature resistance and potentially longer life spans because of their purer composition, which can be beneficial for differentials. Some synthetic oils might include friction modifiers, but the choice between synthetic and conventional can depend on your vehicle’s specific needs and manufacturer recommendations.

Are there other gear oil additives that are important for differential maintenance besides friction modifiers?

Absolutely, additives such as anti-wear agents, rust inhibitors, and viscosity stabilizers complement friction modifiers by offering protection against a range of potential issues, ensuring holistic care for your vehicle’s differential.

What are the signs that my differential might need more than just a routine addition of a friction modifier?

If you notice unusual noises, chattering during turns, or excessive wear despite regular maintenance, this could indicate that your differential requires more extensive repairs or a different type of friction modifier. Consult a professional mechanic for a thorough diagnosis and appropriate treatment.