Fix: Limited Slip Differential Not Working

If you’re experiencing challenges with your limited slip differential, you’re not alone. This critical component, which provides traction by evenly distributing power between the wheels, can sometimes fail to lock correctly, resulting in frustrating one-wheel spins. Understanding how to fix a limited slip differential and undertaking a proper limited slip differential repair can effectively address and solve these automotive headaches.

Whether you’re the proud owner of a robust vehicle like the 2006 F-250 with a 3.73 LS rear diff, or another model sporting this traction-aiding technology, troubleshooting your limited slip differential is key to maintaining optimal performance. Concerns typically arise when clutches within your differential wear down or when the fluid lacks the necessary friction modifier, prompting the need for a repair or, in some cases, a complete overhaul of the system with more reliable aftermarket alternatives.

Key Takeaways

- Persistent one-wheel spins may indicate an issue with your vehicle’s limited slip differential.

- A traction lock rebuild kit can be beneficial for vehicles with a three pinion carrier, like specific F-250 models.

- Before complete system replacement, trying new oil without a friction modifier might temporarily lock a failing unit.

- More reliable alternatives, such as TruTrac or Detroit lockers, are recommended for replacing original clutch-based systems.

- Thorough diagnostics are advised, including inspecting clutch wear and fluid conditions before deciding on a fix.

- Regular maintenance is crucial in preventing limited slip differential problems from arising.

Understanding Your Limited Slip Differential

When you’re navigating tight corners or traversing slippery surfaces, your vehicle’s limited-slip differential (LSD) is a key player in maintaining traction. It’s sophisticated hardware that requires regular attention to ensure it’s operating effectively. However, not all LSDs are created equal, and understanding the distinction between different types can be crucial for maintenance and troubleshooting. Here’s a look into the components, functionality, and variety of LSD units you may encounter.

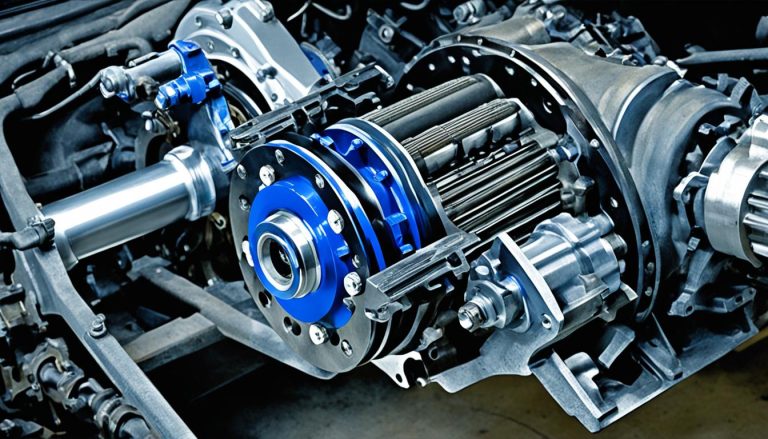

Components and Functionality of an LSD

Your limited-slip differential is engineered to distribute power to the wheels of your vehicle efficiently. When one wheel loses grip, the LSD’s clutches transfer torque to the wheel with better traction. This division of power is critical for your vehicle’s handling and stability. A common issue with limited slip differentials, especially prevalent in certain models, is the premature wear and tear of these clutches. The not working LSD can manifest as a lack of power transfer, resulting in visible performance lags.

Limited slip differential maintenance is central to keeping these clutches and other components, such as the springs and gears, in prime condition. In vehicles like the 2006 F-250, with its factory-installed LSD, failure to maintain the differential properly has led to issues that could hinder its performance.

Factory-Installed vs. Aftermarket LSD Units

| Feature | Factory-Installed LSD | Aftermarket LSD |

|---|---|---|

| Durability | Less durable clutches | Robust design for longevity |

| Performance | May require frequent rebuilds | Consistent and high-performing |

| Maintenance | More sensitive to maintenance lapses | Better tolerance to varied conditions |

| Cost | Lower initial cost | Higher initial cost but better value over time |

While both factory-installed and aftermarket LSDs serve the same fundamental purpose, there is often a notable difference in their durability and maintenance needs. Several truck owners report that the Auburn units installed in their vehicles were not as reliable, leading to common issues with limited slip differentials and prompting them to seek sturdier aftermarket alternatives like the TruTrac. Choosing between maintaining your current LSD and upgrading to an aftermarket option involves evaluating these factors critically, considering your vehicle’s demands and your driving conditions.

Whether you’re dealing with a limited slip differential not working or just performing regular limited slip differential maintenance, recognizing the signs of wear and understanding your vehicle’s specific needs will go a long way toward ensuring smooth and safe driving experiences.

Spotting the Signs of Limited Slip Differential Failure

As a vehicle owner, you might be familiar with the superior traction a limited slip differential (LSD) is supposed to offer. Yet, for those who face unexpected LSD problems, understanding the signs of limited slip differential failure is crucial for maintaining your vehicle’s performance. Let’s dive into the subtle cues that could suggest your LSD is not functioning as intended.

The first and most conspicuous sign is when you notice a persistent one-wheel spin. If your car fails to send power to both wheels under conditions that require additional traction—such as when you’re stuck in mud or during a sharp turn—this is often the initial red flag signaling potential limited slip differential problems.

- Inconsistent performance during regular driving

- Unusual noises, such as clicking or banging, from the differential during turns

- Excessive tire wear, suggesting that the tires are not receiving equal power

- Changes in handling characteristics, especially under acceleration

Even if your vehicle is relatively new, don’t dismiss these symptoms. For instance, thread discussions have shown newer vehicles with as little as 10,000 miles facing LSD failure, wherein drivers discovered the LSD had become non-responsive suddenly, evidenced by the one-wheel spin situation.

“After my fluid change, the LSD was as good as dead. Never expect your components to last forever—always keep a lookout for these warning signs.”

Lastly, don’t ignore the changes that come after servicing your vehicle. Any erratic behavior following a differential fluid change could indicate issues within the unit. It’s not just about detecting problems but also being proactive in checking the health of your LSD before a minor issue leads to a full-blown failure.

Remember, paying attention to your vehicle is the best way to ensure a long life for your differential. Keep these symptoms in mind, and you’ll have an early warning system in place, able to thwart more severe limited slip differential problems before they worsen.

Common Issues with Limited Slip Differentials

When your vehicle’s performance doesn’t quite grip the road as it used to, it could point to limited slip differential slipping or other related issues. Understanding these common problems is key to maintaining optimal drivability and longevity of your vehicle’s components.

Clutch Wear and Its Impact on Performance

If you’re experiencing a loss of traction, this could be due to clutch wear inside your limited slip differential. Using this essential component under high stress can lead to accelerated wear, often resulting in insufficient power distribution between wheels. This is especially true for vehicles equipped with stock units, which are not as robust as aftermarket alternatives.

Friction Modifier: Too Much or Too Little?

Another critical factor affecting your differential’s performance is the delicate balance of the friction modifier in the differential fluid. The improper amount of this additive can lead to clutches engaging and disengaging erratically, producing unwanted noise and wear, a term often referred to as “chatter”. To counter these limited slip differential problems, using a product such as Lubegard Limited Slip Supplement can make all the difference in giving your fluid just the right properties to perform smoothly.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Clutch Wear | Reduced traction, slipping differential, uneven tire wear | Inspect and replace worn clutches, consider aftermarket upgrades |

| Incorrect Friction Modifier Levels | Noise on turns, “chatter”, inconsistent engagement | Adjust the friction modifier amount, fluid change, supplement addition |

With these insights, you’re better equipped to understand and diagnose when something isn’t quite right with your vehicle’s limited slip differential. Remember, a proactive approach to maintenance can save you both time and money while keeping your drives smooth and secure.

Step-by-Step Guide to Troubleshooting Your Limited Slip Differential

If you’re experiencing trouble with your vehicle’s limited slip differential (LSD), a systematic troubleshooting approach can help you pinpoint and resolve the issue. Here’s a friendly, step-by-step guide to troubleshooting limited slip differential to get you back on the road with confidence.

Initial Symptom Checker

- Check for one-wheel spin in a traction-demanding scenario.

- Listen for any unusual noises when turning corners, which may indicate a worn clutch.

Confirming Functionality

- Replace the differential oil without adding a friction modifier and test the locking functionality.

- Perform a visual inspection of your LSD: open the differential case and check for physical signs of clutch wear using feeler gauges.

- Assess the differential’s backlash and pinion depth for potential issues.

Reconditioning the Clutch Pack

- To address stickiness from prolonged straight-line driving, actively drive your vehicle and perform tight circles to re-wet the clutch pack.

Tackling limited slip differential troubleshooting with patience and precision can save you time and resources. Keep a record of your findings throughout the process to assist professionals if further intervention is needed.

Remember that regular maintenance is key to keeping your limited slip differential functioning at its best. Establishing a routine check can prevent many of the common issues associated with LSDs. If you need professional assistance, don’t hesitate to contact a certified mechanic who can provide the expertise required for more complex repairs.

Limited Slip Differential Maintenance to Prevent Future Problems

Maintaining your vehicle’s limited slip differential (LSD) is critical to ensure peak performance and longevity. Neglect in this department can lead to early wear and costly limited slip differential repairs down the line. Let’s explore the key maintenance steps you should take to keep your LSD in prime condition.

Regular Fluid Checks and Changes

One of the most crucial aspects of limited slip differential maintenance is the regular inspection and replacement of its fluid. Over time, differential fluid breaks down, which can lead to increased friction and heat – enemies of your LSD’s sensitive internal components. By performing periodic fluid checks, you can detect if the fluid has become contaminated with metal shavings or has broken down, which are signs your differential is due for a fluid change.

Adding the Right Type of Friction Modifier

Clutch-based LSDs rely heavily on the type and amount of friction modifier within the gear lubricant. If the wrong type or quantity is used, it can lead to improper clutch engagement, resulting in unwanted noise known as “chatter.” To prevent this and ensure smooth operation, it’s essential to add the right type of friction modifier and adjust the quantity based on your vehicle’s performance after service.

To help you keep track of these critical maintenance tasks, here’s a handy table:

| Maintenance Task | Frequency | Significance |

|---|---|---|

| Check LSD Fluid Level | At every oil change | Ensures proper lubrication and reveals potential leaks |

| Change LSD Fluid | Every 30,000 miles or as specified by the manufacturer | Prevents breakdown of fluid properties which can cause LSD failure |

| Add/Adjust Friction Modifier | With every fluid change or when chatter is detected | Optimizes clutch engagement and prevents premature wear |

By adhering to these guidelines for limited slip differential maintenance, you can help ensure that your vehicle’s LSD continues to function as expected, providing you with the traction and performance you need. Always refer to your vehicle’s manual for the most accurate maintenance schedule and procedures, and when in doubt, consult with a trusted automotive technician who is experienced in limited slip differential repair.

Tips for Repairing a Limited Slip Differential

When your limited slip differential starts to show signs of wear or failure, you’re faced with an important decision: should you attempt limited slip differential repair with OEM parts, or go for a complete limited slip differential replacement? It’s a tricky choice, but with a few expert pointers, you can make an informed decision that will ensure your vehicle remains in top condition.

When to Rebuild vs. Replace

Rebuilding your limited slip differential with original equipment manufacturer (OEM) components may seem cost-effective; however, it might not be the best long-term solution. The truth is, stock parts, like those from the Auburn clutch system, might not offer the resilience or performance you need. If you find yourself rebuilding more often than you’d like, it might be time to consider replacement options that offer enhanced durability and longevity.

Choosing the Right Replacement: LSD Options

For a definitive solution, upgrading to a more robust system like the TruTrac can be a wise investment. Gear-driven rather than clutch-based, this option is popular for its reliability and maintenance ease. Let’s not forget the importance of model compatibility: for trucks such as an F-250 with a 10.5″ rear diff, it’s crucial to source the correct parts. An excellent choice in this scenario would be a Detroit True-Trac Differential known for its precise fit and exceptional performance. Ensure you’re armed with the complete part number and installation guide to make the process seamless.

Ultimately, whether you choose to repair or replace your LSD, the aim is the same: to get back on the road with confidence in your vehicle’s handling and traction. Remember, investing a little more now can save a lot of hassle (and money) in the future.

Limited Slip Differential Not Working: Advanced Solutions

If you’re experiencing problems with your limited slip differential slipping, it may be time to look beyond basic fixes. Temporary measures, like adjusting lubrication or experimenting with friction modifiers, can offer short-term relief but they don’t address the core issue. For a more definitive resolution, many vehicle experts and seasoned drivers favor aftermarket upgrades over trying to repair a faltering OEM unit.

The Eaton TruTrac has gained popularity among those in need of a reliable solution. Its gear-driven design stands in stark contrast to the traditional clutch systems which are more susceptible to wear and tear. Should you find your limited slip differential not working as expected, switching to a TruTrac could save you from repetitive breakdowns and maintenance woes. Moreover, this choice is not merely about enduring quality; it’s an investment in peace of mind when you’re navigating challenging conditions that demand optimal traction from your vehicle.

Ultimately, aiming for the Detroit True-Trac or a similar robust replacement offers a significant upgrade for specific truck models like the F-250. While the initial cost might be higher, the longevity and performance of a high-quality LSD mean more time driving with confidence and less time under the hood. Remember, a smooth-running differential is key to your vehicle’s overall health and your satisfaction on the road.

FAQ

How do I fix a limited slip differential that’s not working?

Resolving a limited slip differential problem may include refilling the differential with new oil without a friction modifier to see if it locks as expected. If issues persist, you might need a traction lock rebuild kit, or for more severe cases, replacing the unit with a more reliable differential like the TruTrac or Detroit locker.

What are the components and functionality of a limited slip differential?

A limited slip differential (LSD) is usually composed of a set of clutches or gears that work together to distribute power evenly across the drive wheels. When one wheel starts to spin, the LSD adjusts to distribute more power to the wheel with better traction. This is critical for maintaining control and stability in varying driving conditions.

How do factory-installed LSD units compare to aftermarket options?

Factory-installed LSD units, like the Auburn clutches in certain trucks, are sometimes less durable than aftermarket options. They can wear out more quickly and may not perform as efficiently, leading some owners to prefer aftermarket differentials like the TruTrac or Detroit lockers, which are known for robustness and longevity.

What are the signs of limited slip differential failure?

Common signs include persistent one-wheel spin, especially in situations that require more traction like getting stuck in mud or snow. You may also notice excessive noise or “chatter” from the differential, especially after a fluid change that may not have included the correct amount of friction modifier.

What impact does clutch wear have on limited slip differential performance?

Clutch wear can significantly reduce the effectiveness of an LSD, leading to situations where the differential fails to provide the necessary power distribution between the wheels. Worn clutches may result in the differential not engaging properly, and you could experience slipping or loss of traction.

What issues can arise from incorrect levels of friction modifier?

Both an excess and a lack of friction modifier can cause problems. Too much modifier can prevent the clutches in the LSD from engaging fully, resulting in slipping, while too little can lead to harsh engagement, noise, or “chatter”, and potentially premature wear of the clutch plates.

How do I troubleshoot a limited slip differential?

Begin troubleshooting by checking if the differential is engaging properly through a traction test. Change the differential fluid without adding a friction modifier initially to see if this solves the issue. If not, inspect the clutch wear manually and verify the differential’s internal measurements like backlash and pinion depth for any discrepancies.

What does limited slip differential maintenance involve?

Regular fluid checks and changes are crucial, along with using the correct type of friction modifier. Monitoring and adjusting the amount of friction modifier after service is essential to maintain the proper clutch engagement and ensure the longevity of an LSD.

When should I rebuild versus replace my limited slip differential?

Consider rebuilding if the issue is minor and the unit has not experienced significant wear. However, if you have a stock Auburn unit that has repeatedly failed, or if repair costs are high, replacing it with a more durable aftermarket option, such as the TruTrac or Detroit locker, may be more cost-effective in the long term.

How do I choose the right replacement limited slip differential?

When selecting a replacement LSD, consider the type of driving you do, your vehicle’s specifications, and the known durability of aftermarket brands. Gear-driven options like the TruTrac are often preferred for their reliability. Make sure to select a differential that is compatible with your vehicle, such as the Detroit True-Trac for trucks with a specific rear diff size.

What advanced solutions are available if my limited slip differential isn’t working?

Advanced solutions include installing a more robust aftermarket LSD like the TruTrac or Detroit locker. These options typically offer better performance and longevity, especially if lubrication adjustments or rebuilds with OEM parts haven’t resolved the issues with your limited slip differential.