Best Transmission Cooler Lines for Your Vehicle

Maintaining an optimal temperature for your vehicle’s transmission is crucial for performance and longevity. That’s where transmission cooler lines come into play. These specially designed lines are essential for any vehicle, ensuring that the transmission fluid is properly circulated and cooled. With the right transmission cooler kit and precise transmission cooler line fittings, drivers can safeguard their transmission from the detrimental effects of overheating, securing both functionality and peace of mind.

Key Takeaways

- Quality cooler lines preserve transmission fluid integrity and prevent overheating.

- Choosing the right cooler line fittings is essential for a leak-proof system.

- Proper maintenance of transmission cooler lines is a wise investment for vehicle longevity.

- High-performance vehicles benefit from upgraded kits designed to withstand elevated temperatures.

- Regular checks on transmission cooling systems can prevent costly future damages.

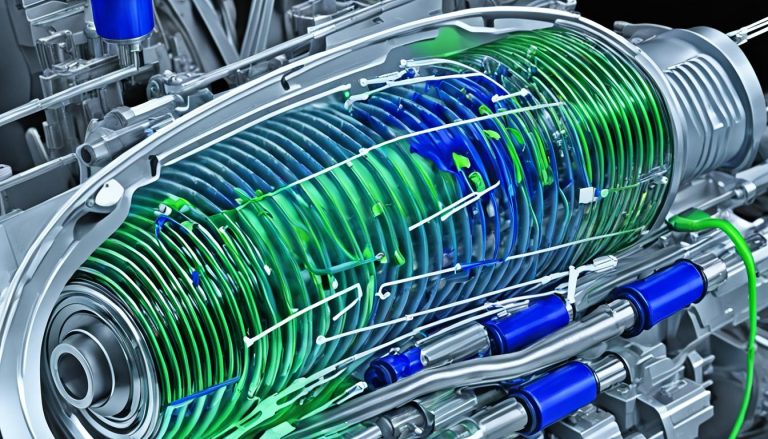

Understanding the Function of Transmission Cooler Lines

The complexity of an automatic transmission system highlights the significance of each component working in harmony. Amongst these, the transmission cooling line carries the responsibility of controlling the heat levels within the transmission. This simple yet crucial part plays an indispensable role in managing the automatic transmission fluid (ATF), ensuring optimal performance even under stress.

Role of Cooler Lines in Vehicle’s Transmission System

Transmission oil cooler lines serve as the vital passageways for transferring ATF from the transmission to the oil cooler set within the radiator. This process is critical in maintaining the fluid within the ideal temperature range. By doing so, they protect against the dangers of overheating, a common enemy of transmission systems. The lines ensure that the ATF consistently absorbs and dissipates heat, preventing any performance hindrances.

Impact of Overheating on Transmission Longevity

Facing excessive temperatures can be catastrophic for any transmission. A vehicle enduring conditions where the ATF exceeds 270°F is at significant risk; such overheating can deteriorate the transmission fluid quality, leading to the failure of internal components. Extended exposure to these elevated temperatures can warp metal parts and disrupt the delicate balance required for smooth gear shifts and drivability. Investing in a durable transmission oil cooler line mitigates these risks and is indispensable for a long-lasting transmission.

Typical Operating Temperature Ranges for Transmission Fluid

For smooth operations, an automatic transmission’s fluid should generally be kept at temperatures between 175°F and 200°F. Maintaining this range is a primary function of cooler lines and is crucial for the transmission to perform efficiently. Should the temperature sway beyond these limits, the risk of damage exponentially increases. Regular monitoring, coupled with a reliable transmission cooling line system, can ensure that the fluid’s operating temperature remains under control.

Understanding these aspects of transmission maintenance is key to preventing costly repairs and ensuring the longevity of your vehicle’s transmission system. Appropriate attention to these components keeps the transmission in top condition, ready to face the demands of both city commutes and long highway journeys.

Selecting the Ideal Transmission Cooler Lines for Your Needs

When evaluating your vehicle’s transmission cooling system, a crucial step is contemplating the most appropriate transmission cooler lines replacement. If faced with a malfunction or wear and tear, using a transmission cooling line repair kit might be the necessary solution. However, you must take into account various essential aspects to ensure the longevity and effectiveness of your transmission.

Identifying the right transmission cooler hose is not only about compatibility; it’s also about resilience to the demanding environment under the hood. The material should withstand fluctuations in temperature and pressure without compromise. Traditional choices may range from pre-fabricated metal lines that offer a precise fit, to more adaptable rubber hoses suited for quick fix or unconventional routing configurations.

- Assess your transmission type: Whether you have an automatic or manual transmission will influence your choice in cooler lines.

- Review the configuration: Understand the layout of your existing cooling system to determine which lines or kits will be compatible.

- Consider vehicle-specific requirements: Take note of any manufacturer recommendations or unique attributes of your vehicle model.

For drivers in pursuit of engine optimization or handling high-performance vehicles, options extend to advanced setups including AN fittings and PTFE hoses, known for their exceptional heat resistance.

| Type of Cooler Line | Material | Best For | Temperature Resistance |

|---|---|---|---|

| OEM Metal Lines | Steel, Aluminum | Direct Fit/Replacement | High |

| Rubber Hoses | Reinforced Rubber | Temporary or Custom Fits | Moderate |

| AN Fittings & PTFE Hoses | Polymers with Teflon™ layers | High-Performance Vehicles | Very High |

Opt for a pre-bent OEM line that ideally matches the original design for straightforward replacements. But in a custom application, where flexibility and durability are desired, turning to a transmission cooler hose can offer the necessary adaptability.

Ultimately, the best course of action might not just be about replacing what’s broken, but improving the transmission system for future resilience, performance, and peace of mind.

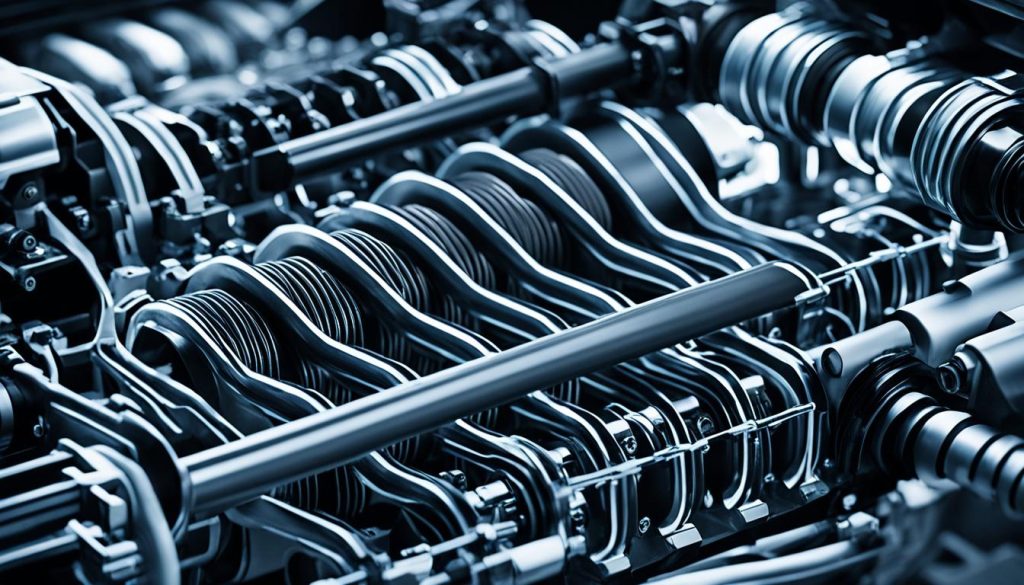

Durable Materials for High-Performance Transmission Cooler Lines

Transmission systems in high-performance vehicles require reliable components that can endure extreme conditions. This is where advanced materials for transmission cooler lines come into play, ensuring efficiency and longevity. Specifically, PTFE hoses and steel braided lines have become increasingly popular due to their outstanding properties in handling high temperatures and pressures associated with transmission cooler flush operations and more.

Benefits of Using PTFE Hoses in Transmission Cooling

The adoption of PTFE hoses in the realm of transmission oil cooler hoses has brought about transformative advantages. Their innate chemical resistance and tolerance to high temperatures make them ideal for preserving integrity during the cooling process. Drivers of high-performance vehicles that push the limits will appreciate the resilience of PTFE hoses when a transmission cooler flush is performed—assuring that the system is cleared of contaminants without damaging the hardware.

Advantages of Steel Braided Lines for Heat and Pressure Resistance

Steel braided lines are renowned for their strength and durability. These lines, often composed of a flexible inner tube encased in a woven steel mesh, offer an unmatched level of protection. In the most demanding environments—such as in racing applications—the steel braided lines maintain their structural integrity. The combination of heat resistance and pressure tolerance inherent to steel braided lines results in an ideal solution for those seeking a reliable and consistent performance from their transmission oil cooler hose.

| Material Type | Temperature Resistance | Pressure Resistance | Chemical Resistance | Application Scenario |

|---|---|---|---|---|

| PTFE Hose | High | Moderate-to-High | Excellent | Racing, High-Performance |

| Steel Braided Line | Very High | Very High | Good | Racing, Heavy Duty Applications |

Signs of Wear: Identifying When to Replace Your Transmission Cooler Lines

Vehicle owners recognize the importance of a healthy transmission system. Integral to this system are the transmission cooler lines, which are vital for preventing overheating. It’s crucial to know the signs of transmission cooler lines leaking and understanding precisely when to replace transmission cooler lines to safeguard your vehicle’s performance. Here are the warning indicators that demand immediate attention:

- Visible Leaks: Pools of red fluid under your vehicle can be a telltale sign of transmission fluid leakage, stemming from compromised cooler lines.

- Discoloration or Contaminants: If the transmission fluid appears dark or contains debris, this could signal internal issues or degradation of the cooler lines.

- Transmission Overheating: A vehicle that struggles with consistent overheating warrants a check of the cooler lines, which may be restricted or damaged.

- Erratic Transmission Performance: When the cooler lines are failing, your vehicle may experience slipping or difficulty in gear shifting.

Learning to spot these early warnings of transmission cooler line deterioration can prevent costly repairs and sustain your vehicle’s longevity. Proactive maintenance is crucial, and timely replacement of these components will enable a smooth driving experience.

| Symptom | Possible Cause | Immediate Action Required |

|---|---|---|

| Fluid Leakage | Worn or damaged cooler lines | Inspect and replace cooler lines |

| Transmission Overheating | Blockage or leak in cooler lines | Flush system and replace lines if necessary |

| Erratic Transmission Behavior | Lack of fluid or pressure due to leaks | Check line integrity and fluid levels |

It’s not just about preventing leaks or avoiding overheating; changing your transmission cooler lines at the right time is about preserving the seamless operation of your vehicle. Keeping an eye on the condition of your transmission cooler lines is a small step that can lead to a leap in your vehicle performance and dependability.

Installation Tips for Transmission Cooler Lines

Ensuring your vehicle’s transmission remains cool under pressure is critical. The process of transmission cooler line repair can be streamlined with the use of proper tools and techniques. This section will discuss different types of fittings and clamps used for secure installation and provide pointers on achieving a leak-proof setup for your cooler lines.

Common Fitting Types and Their Applications

If you’re tackling a transmission cooler line repair, choosing the right type of fittings is crucial. The type of fitting you’ll need can vary based on your vehicle’s make and the specific demand of the transmission system. Two predominant choices in the aftermarket are AN fittings and barb fittings. AN fittings are known for their ability to create a secure, tight connection, making them excellent for high-performance scenarios. On the other hand, barb fittings are often favored for their simplicity and ease of installation, particularly in less demanding applications.

Securing Transmission Cooler Lines with the Appropriate Clamps and Connectors

Once you’ve selected your fittings, the next step is securing them in place. Hose clamps are simple yet vital components in ensuring your transmission cooler lines stay affixed and leak-free. When choosing hose clamps, it’s crucial to match the clamp to the size and type of hose you’re working with to ensure optimal security. Here’s a comparative look at prevalent hose clamp types.

| Type | Description | Best Used For |

|---|---|---|

| Worm Gear Clamps | Metal clamps with a screw mechanism for adjustment | Universal applications, easy to install and adjust |

| Spring Clamps | Provide constant tension, usually made from spring steel | Simple installations where space and flexibility are paramount |

| T-Bolt Clamps | Solid band with a bolt and nut tightening system | High-pressure connections where a uniform seal is needed |

| Ear Clamps | One-time-use clamp secured with a specialized tool | Secure permanent installation where space is limited |

Remember, meticulous installation mitigates the risk of transmission overheating. By using high-quality AN or barb fittings and ensuring the hose clamps are snug and correctly sized, you’ll have a dependable transmission cooling system that stands the test of time and rigor of the road. Trust in these components and installation tips to keep your vehicle running smoothly.

Optimizing Your Vehicle’s Transmission Temperature with Cooler Lines

The engine’s roar is synonymous with power on the road, yet an unsung hero lies beneath—the transmission system, brought to optimal performance through efficient transmission cooling lines. For Ford enthusiasts, understanding the intricacies of Ford transmission cooler lines is not just about maintenance but about ensuring your vehicle operates at its peak. The heartbeat of this system lies in the steady flow of the transmission fluid, cooled and cycled back into the system, a task charged to transmission cooler line maintenance.

Whether cruising city streets or commanding the rugged terrain, your vehicle relies on a network of transmission cooling lines to maintain the transmission at an ideal temperature. The consolidation of quality materials with meticulous care arms your transportation with the tools to tackle the uncertain paths ahead.

| Transmission Line Type | Material | Benefits | Maintenance Tips |

|---|---|---|---|

| OEM Metal Lines | Steel or Aluminum | Durability and direct fit for standard applications | Regular inspections for rust or corrosion |

| PTFE Lines | Polytetrafluoroethylene | High resistance to heat, ideal for performance vehicles | Check for secure fittings, especially after intense drives |

| Rubber Hoses | Synthetic Rubber | Flexibility for custom setups | Replace if any swelling, abrasions, or deterioration occurs |

| Braided Lines | Stainless Steel or Nylon | Heat and pressure resistance, suitable for harsh conditions | Ensure braided layer is intact with no frays or cuts |

Each material brings its unique strengths to the forefront—sturdy OEM lines configured precisely for your Ford, PTFE’s resilience against high temperatures for the spirited driver, or the practicality of rubber hoses for the custom enthusiast. However, the consistent theme throughout these choices is the necessity for diligent transmission cooler line maintenance. Regular checks can thwart the silent climb of heat that threatens your journey.

Transmission Cooler Lines: A Comparison of Rubber versus Braided Options

Choosing the right transmission cooler lines is crucial for the health and performance of your vehicle’s transmission system. With options ranging from rubber transmission hoses to more resilient braided lines, it’s essential to understand the benefits and setbacks of each to make an informed decision for your automotive needs.

Risks and Considerations When Using Rubber Hoses Near Hot Components

Rubber transmission hoses are known for their cost-effectiveness and adaptability. However, when used in environments with high temperatures, such as near the engine or exhaust system, they can degrade much more quickly. This degradation presents the risk of leaks, which can lead to a drop in transmission fluid pressure and potential transmission damage.

Why Braided Lines May Be the Superior Choice for Certain Vehicles

For vehicles that operate under high stress or high temperatures, nylon braided lines and steel braided transmission hoses offer a more robust solution. Their ability to withstand higher pressures and temperatures makes them an ideal choice for performance vehicles or heavy-duty applications.

| Feature | Rubber Transmission Hoses | Nylon Braided Lines | Steel Braided Transmission Hoses |

|---|---|---|---|

| Material Flexibility | High | Medium | Low |

| Heat Resistance | Low | High | Very High |

| Pressure Tolerance | Low | Medium to High | High to Very High |

| Cost | Lower | Mid-range | Higher |

| Durability | Good | Better | Best |

| Recommended Use | Standard Applications | Performance Applications | High-performance and Heavy-duty Applications |

When selecting cooler lines, it is crucial to consider the specific demands of your vehicle and driving habits. While rubber transmission hoses offer a viable solution for less intense applications, the superior heat and pressure resistance of nylon braided lines and steel braided transmission hoses might be necessary for vehicles that encounter extreme conditions.

Maintenance Best Practices for Transmission Cooler Lines

Preserving the integrity and performance of your vehicle’s transmission system necessitates diligent maintenance. Key to this routine is the upkeep of transmission cooler lines, which are fundamental in managing the thermal state of your transmission fluid. Vehicle owners should prioritize regular fluid checks to ensure the transmission fluid maintains its vital lubricating and cooling properties. Typically, it is advisable to change the fluid every 30,000 to 60,000 miles, though this may vary depending on vehicle use and manufacturer recommendations.

The responsibilities of a car owner also extend to careful examination of transmission cooler line fittings. These critical components should be inspected routinely for signs of wear or leaks. Ensuring the fittings are secure and intact can be the difference between a well-functioning cooling system and one that is prone to overheating and related complications. Such vigilance not only preserves the efficiency of the transmission cooler lines but also extends the lifespan of the entire cooling system.

At the heart of effective system maintenance is the practice of regular fluid checks, integral for detecting early signs of potential problems. Discoloration or a drop in fluid level can indicate a leak or degradation of the cooler lines. Immediate attention to these symptoms allows for timely intervention, potentially averting more significant issues down the line. By following these best practices, vehicle owners can ensure the reliability and durability of their transmission cooling system for miles to come.

FAQ

What is the primary function of transmission cooler lines?

Transmission cooler lines are designed to maintain the temperature of the transmission fluid within a safe operating range. They transfer hot fluid from the transmission to the cooler or radiator to be cooled and then return the cooled fluid back to the transmission.

Why is overheating a concern for a vehicle’s transmission?

Overheating can cause significant damage to a vehicle’s transmission, leading to warped components, fluid breakdown, and reduced transmission efficiency and longevity. It’s critical to keep the transmission well-cooled to prevent these issues.

At what temperature does transmission fluid typically operate?

Transmission fluid typically operates within the temperature range of 175°F to 200°F. Exceeding 270°F is often considered overheating and can lead to transmission failure.

When should transmission cooler lines be replaced?

Transmission cooler lines should be replaced if there are any visible leaks, blockages, or signs of wear and tear. Regular inspection can help identify these issues early and prevent overheating or other transmission problems.

What are some common fitting types for transmission cooler lines?

Common fitting types for transmission cooler lines include standard threaded fittings, barb fittings for easy installation, and AN fittings for a robust connection in high-performance applications.

How do I ensure my transmission cooler lines are securely installed?

To ensure transmission cooler lines are securely installed, use the appropriate clamps and connectors for the type of line and fittings you have. Worm clamps, spring clamps, and AN fittings are some options that can provide a secure installation.

What are PTFE hoses and how do they benefit transmission cooling systems?

PTFE hoses are made from a high-grade material that offers excellent chemical resistance and can withstand high temperatures. They are beneficial for transmission cooling systems in high-performance vehicles due to their durability and reliability under tough driving conditions.

What are the advantages of steel braided lines for transmission cooling?

Steel braided lines are reinforced with a steel mesh layer, which provides exceptional protection against high temperatures and pressures. They are durable and reliable, making them ideal for demanding driving conditions and ensuring longevity of the cooling system.

Why might rubber hoses be less desirable for transmission cooler systems in certain scenarios?

Rubber hoses, while cost-effective and flexible, can be susceptible to damage from heat if installed near hot car components like the exhaust system. This might lead to premature wear and potential failure of the transmission cooling system.

Why might braided lines be a better choice over rubber hoses for some vehicles?

Braided lines, such as nylon braided or steel braided hoses, offer superior durability and resistance to heat and pressure. This makes them more reliable, particularly in high-performance or heavy-duty applications where heat and mechanical stress are common.

What are some maintenance best practices for transmission cooler lines?

Maintenance best practices for transmission cooler lines include regular inspection for leaks or damage, ensuring fittings are secure, and regular fluid checks. Transmission fluid changes are generally recommended every 30,000 to 60,000 miles to maintain proper lubrication and cooling properties.