Troubleshooting Limited Slip Differential Problems

When you’re hitting the road, you expect your vehicle’s handling to be top-notch, especially in conditions where every bit of traction counts. A key player in keeping you glued to the pavement is your vehicle’s limited slip differential (LSD). But when common limited slip differential issues arise, they can turn your smooth ride into a bumpy ordeal. Understanding how to fix limited slip differential problems is crucial in maintaining optimal performance and extending the life of your differential.

Whether you’re navigating a sharp corner on a wet street or powering through an uneven terrain, a well-maintained LSD is integral to your vehicle’s power distribution. But what happens when the unexpected occurs? From unsettling noises to decreased performance, troubleshooting limited slip differential challenges doesn’t have to be an overwhelming process. Let’s explore how to spot potential issues and proactively tackle them head-on for an uninterrupted driving experience.

Key Takeaways

- Identify common limited slip differential issues to prevent major repairs.

- Understand the symptoms and signs that suggest your LSD might be failing.

- Learn the steps for how to fix limited slip differential problems before they escalate.

- Get to know the importance of the correct fluid and additives for your LSD.

- Recognize the vital role that regular maintenance plays in LSD performance.

- Appreciate the significance of timely troubleshooting in safeguarding your differential.

Understanding the Role of Limited Slip Differentials in Vehicle Performance

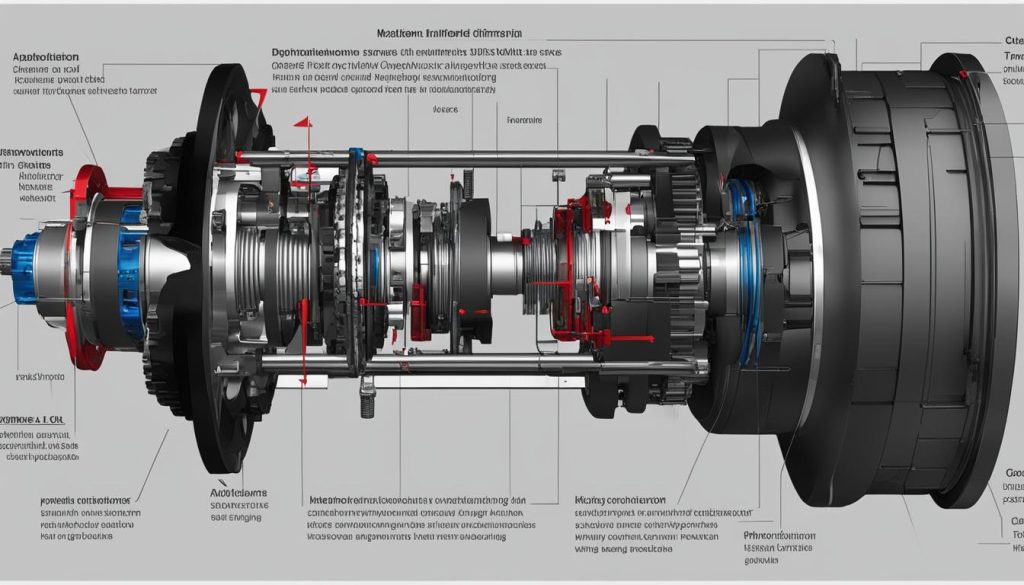

When it comes to enhancing vehicle performance with LSD, your driving experience is transformed through advanced traction management. The key difference between limited slip differential vs open differential lies in how power is distributed to the wheels. Limited slip differentials (LSD) are adept at providing increased grip and control, ensuring that your vehicle can power through various driving conditions with precision.

Whether you’re navigating icy roads or executing high-speed cornering maneuvers on a racetrack, an LSD is crucial for maintaining the balance between wheels. This is in stark contrast to open differentials, which tend to send power to the wheel facing the least resistance, often leading to wheel spin and reduced vehicle control.

Limited slip differential maintenance is essential for preventing a decline in efficiency and managing traction-related problems. Proper care will not only extend the lifespan of your vehicle’s differential but also ensure that the driving experience remains top-notch.

| Feature | Open Differential | Limited Slip Differential |

|---|---|---|

| Power Distribution | Directs power to the wheel with less resistance | Evenly distributes power to all wheels |

| Traction Control | Struggles on slippery and uneven surfaces | Improves traction on diverse terrains |

| Performance in Corners | Prone to understeer and wheel spin | Enhanced grip and stability during sharp turns |

| Maintenance | Typically lower maintenance | Requires periodic maintenance for optimal performance |

Remember, whether you’re a daily driver or an automotive enthusiast, understanding and maintaining the components that contribute to your vehicle’s performance, like the LSD, is key to an exhilarating and safe driving experience.

Recognizing Signs of Limited Slip Differential Failure

When your vehicle’s performance starts to waver, it could be a alert from your limited slip differential (LSD) asking for attention. Staying mindful of the signs of limited slip differential failure is crucial to maintaining optimal driving conditions and preventing more serious issues down the line. Let’s delve into the common indicators that your LSD might be on the blink.

Unusual Noises and Vibrations from the Differential

If you’ve started to notice limited slip differential noise, such as a grinding or whining, during your drives, this could signal that the differential gears are wearing out or that the fluid levels are inadequate. Vibrations emanating from the differential area should also not be ignored, as they could indicate a misalignment or a worn-out bearing.

The Phenomenon of Chatter During Turns

Another auditory clue is a condition often described as “chatter”, which is most noticeable when taking turns. This occurs when the LSD clutches are not engaging smoothly, often due to the wrong type of lubricant or degraded fluid quality. Regular maintenance, including inspecting LSD for common issues, can mitigate this problem.

Issues with Traction and Handling on Various Terrains

Limited slip differentials are designed to provide better traction on tricky terrain by distributing torque evenly between the wheels. If you’re experiencing handling issues or increased wheel spin, especially on slippery surfaces, it’s a strong indication that something is amiss with your LSD.

Visual Inspection for Leaks and Wear

Taking time for a thorough visual inspection can uncover potential red flags such as oil leaks which may arise from seal wear or breakage. These leaks can lead to lubrication issues that exacerbate wear and tear on your differential’s internal components. Keeping an eye out for signs of damage or abnormal wear is a proactive step in preserving your vehicle’s drivetrain integrity.

Know that understanding and addressing these warning signs early on can save you from the inconvenience and expense of a complete differential overhaul. Remember, if you spot any of these symptoms, it’s best to have your vehicle inspected by a professional who can offer a precise diagnosis and solution. With proper care, your limited slip differential will continue to deliver the performance and reliability you depend on.

Examining Common Limited Slip Differential Issues and Solutions

When you’re faced with reduced vehicle control or worrying noises from your car, it might be time to investigate potential limited slip differential (LSD) complications. Knowing how to fix limited slip differential problems is essential for maintaining your vehicle’s performance and safety. Common indicators of LSD issues include cornering difficulties, gear grinding, and unpleasant vibrations—or worse, a high-pitched whining sound.

Thankfully, resolving LSD problems often begins with a few simple steps. First, ensure your differential’s fluid levels are correct. Low or degraded fluid can cause significant LSD issues. If the fluid level is adequate, it’s crucial to inspect for mechanical damage that may require common limited slip differential repairs, such as replacing worn clutches or gears.

- Regularly check differential fluid levels and conditions.

- Listen for unusual noises or vibrations and investigate their source.

- Perform road tests to replicate the problem and confirm LSD involvement.

Should you discover worn parts or damage, replacing these components promptly can save you from a total LSD failure. However, if troubleshooting feels out of your depth, don’t hesitate to consult a professional mechanic who specializes in drivetrain components. Timely diagnosis and competent repairs are the cornerstones of resolving LSD problems and can significantly extend the life of your car’s differential.

“Regular maintenance and early problem resolution are essential for the longevity of your limited slip differential and overall vehicle performance.”

Remember, a proactive approach to maintenance helps prevent the most common LSD ailments. Don’t wait for total failure—keep your limited slip differential in top shape and enjoy a smooth, controlled drive every time you hit the road.

Limited Slip Differential Maintenance: Prevention is Better Than Cure

When it comes to the well-being of your vehicle’s limited slip differential, regular upkeep plays a critical role. Staying ahead with preventative maintenance not only ensures smoother operation but also extends the life span of your differential. Taking a moment to care for your LSD can save you time and money in the long run, keeping your vehicle in peak condition for those crucial moments when you rely on its performance the most.

Regular Fluid Checks and Replacements

A simple yet effective step in the maintenance of limited slip differential is to conduct regular fluid checks. Keeping an eye on your differential fluid’s quality and level is central to your LSD’s health. With the right care, you can prevent common issues such as overheating and wear. Fluid replacements should be carried out as recommended by your vehicle manufacturer, ensuring that every component of your LSD is lubricated properly for optimal performance.

Choosing the Right Additives to Enhance Performance

Understanding the significance of enhancing LSD performance with additives is likewise essential for maintaining your differential. Additives that are suited to your vehicle’s specific needs can dramatically improve functionality. They work by adjusting the frictional properties of your differential fluid, leading to smoother clutch engagement and preventing disturbing noises and rough handling while turning. Choosing and using the correct additives is akin to fine-tuning your vehicle’s performance to your driving expectations.

Need for Periodic Inspection of Clutch Components

Lastly, to avoid future troubles and unexpected breakdowns, do not overlook the importance of inspecting clutch components in LSD. Regular inspections can reveal early signs of wear and tear or damage, allowing you to address such concerns before they worsen. Keeping your LSD’s clutch components in check contributes to consistent performance and reliability under various driving conditions. Remember, attentive care and periodic inspections fortify your vehicle’s capabilities, ensuring that every journey is both safe and enjoyable.

FAQ

What Are Common Signs of Limited Slip Differential Failure?

Common signs of a failing limited slip differential include unusual noises and vibrations, especially during turns, along with problems in traction and vehicle handling on various terrains. If you notice increased wheel spin, loss of control, grinding gears, or that your car struggles more than usual during cornering, these could be indicators of LSD problems.

How Can I Troubleshoot My Limited Slip Differential Problems?

Troubleshooting limited slip differential issues can involve checking the differential fluid level and quality, looking for any leaks, listening for unusual noises under various driving conditions, and assessing how well your vehicle maneuvers around corners. Inspecting for mechanical damage to gears or clutch components is also a part of the troubleshooting process.

What is the Difference Between a Limited Slip Differential and an Open Differential?

The main difference between a limited slip differential (LSD) and an open differential is how they distribute power to the wheels. An LSD provides balanced power delivery to both wheels, even if one starts to slip, enhancing vehicle performance especially in low traction situations. In contrast, an open differential sends power to the wheel with the least resistance, which can be less effective during slip conditions.

What Maintenance Does a Limited Slip Differential Require?

Limited slip differential maintenance includes regular checks and changes of the differential gear oil to ensure it has the correct frictional properties and isn’t contaminated or degraded. Depending on the type, LSDs may also require specific additives to function properly. Additionally, periodic inspections of the clutch components within the LSD are necessary to catch any potential problems early.

How Can I Enhance My Vehicle’s Performance with an LSD?

Enhancing vehicle performance with an LSD involves proper maintenance, ensuring that the differential fluid is fresh and at the correct level, and using suitable additives like Lubegard Limited Slip Supplement to maintain proper friction. These steps help ensure that the LSD operates correctly, providing better traction and handling, particularly in challenging driving conditions.

What Are Some Common Limited Slip Differential Repairs?

Common limited slip differential repairs might include replacing worn clutch plates, repairing or replacing seals to fix leaks, and refilling or changing the differential fluid. In some cases, damaged gears may need repairing or replacing, and the addition of specific friction modifiers to the gear oil might be required to eliminate chatter and noise.

What Could Cause Chatter During Turns in My LSD?

Chatter during turns in an LSD is typically caused by improper lubrication or worn components within the differential. It can also occur due to a lack of additives in the gear oil needed for the clutch-type LSDs to operate smoothly. Addressing this issue usually involves inspecting the fluid and adding the correct additives or replacing worn parts.

How Can I Recognize Differential Noise That Indicates an LSD Issue?

Differential noise that may indicate an LSD issue can sound like whining, howling, or a rumbling growl, especially noticeable when accelerating or decelerating, and during turning maneuvers. It’s important to distinguish these from normal operational sounds by noting changes in frequency or loudness that correlate with vehicle speed and driving conditions.

Why is It Important to Use the Right Additives in My LSD?

Using the right additives in your LSD is important because they help to modify the friction properties of the differential fluid, ensuring smooth operation of the clutch plates inside a clutch-type LSD. Without these additives, you may encounter issues such as chatter, increased wear of components, and suboptimal performance.

What Should I Do If I Find a Leak in My Limited Slip Differential?

If you find a leak in your limited slip differential, you should have it inspected and repaired as soon as possible. Leaks can lead to a loss of lubrication, which is essential for the proper operation of the differential. This could result in increased friction, overheating, and ultimately, failure of the differential components.